Improving the Quality of Sardine Fish Oil by Degumming Using Sodium Cholride Solution

Abstract

The quality of fish oil is determined by some parameters such as primary and secondary grade oxidation, fatty acid profile and physical qualities which include viscosity, density, color and clarity. Sardine fish oil by-products of fish meal processing can be a source of polyunsaturated fatty acids (PUFAs), particularly

eicosapentaenoic acid (EPA) and docosahexaenoic acid (DHA). Degumming is one of steps that can be carried out to improve the quality of sardine fish oil. The processing will help to reduce oxidation and eliminate the impurity of the oil that influence the quality of fish oil. The purpose of this study was to determine the effect of sodium chloride solution degumming on the quality of sardine fish oil to fulfill International Fish Oil Standard (IFOS). Fish oil purification was done by degumming of 5% H2O, followed

by sodium chloride solution with ratio of fish oil and sodium chloride solution were 1:1; 1:3, and 1:5. The sodium chloride solution concentrations of 5% and 8% for 20, 30 and 40 minutes. The next steps after degumming process were followed by alkali neutralization and bleached by absorbent. The best treatment

was at concentration of 5% sodium chloride solution, ratio fish oil with sodium chloride solution 1:1 on a long time degumming processed 20 minutes. The best quality of fish oil, according to IFOS, was resulted from the treatments combination of free fatty acid 0.21±0.00%, peroxide value 0.43±0.06 mEq/kg, anisidin

value 2.22±0.04 mEq/kg and total oxidation 3.11±0.14 mEq/kg.

eicosapentaenoic acid (EPA) and docosahexaenoic acid (DHA). Degumming is one of steps that can be carried out to improve the quality of sardine fish oil. The processing will help to reduce oxidation and eliminate the impurity of the oil that influence the quality of fish oil. The purpose of this study was to determine the effect of sodium chloride solution degumming on the quality of sardine fish oil to fulfill International Fish Oil Standard (IFOS). Fish oil purification was done by degumming of 5% H2O, followed

by sodium chloride solution with ratio of fish oil and sodium chloride solution were 1:1; 1:3, and 1:5. The sodium chloride solution concentrations of 5% and 8% for 20, 30 and 40 minutes. The next steps after degumming process were followed by alkali neutralization and bleached by absorbent. The best treatment

was at concentration of 5% sodium chloride solution, ratio fish oil with sodium chloride solution 1:1 on a long time degumming processed 20 minutes. The best quality of fish oil, according to IFOS, was resulted from the treatments combination of free fatty acid 0.21±0.00%, peroxide value 0.43±0.06 mEq/kg, anisidin

value 2.22±0.04 mEq/kg and total oxidation 3.11±0.14 mEq/kg.

Authors

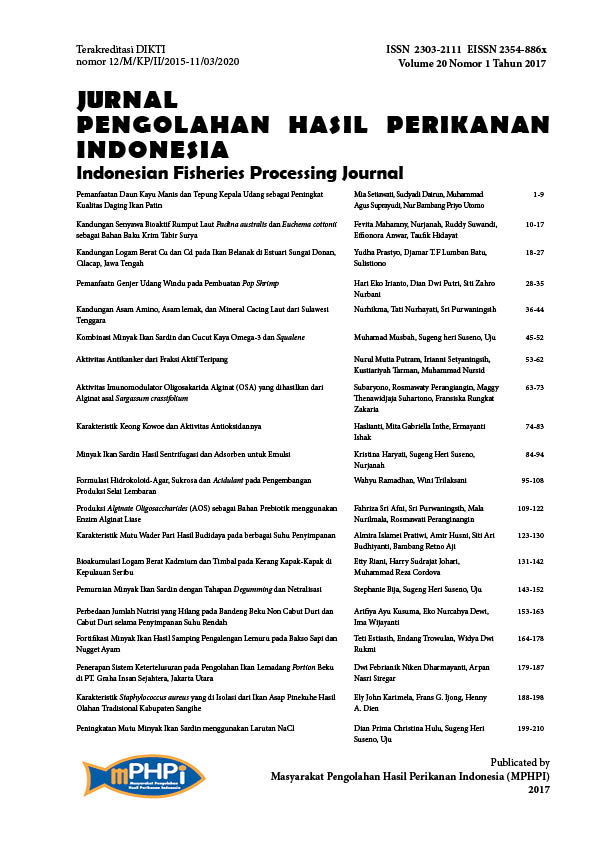

HuluD. P. C., SusenoS. H., & UjuU. (2017). Improving the Quality of Sardine Fish Oil by Degumming Using Sodium Cholride Solution. Jurnal Pengolahan Hasil Perikanan Indonesia, 20(1), 199-210. https://doi.org/10.17844/jphpi.v20i1.16508

Authors who publish with this journal agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgement of its initial publication in this journal.