Development of halal assurance system for shoyu production

Abstract

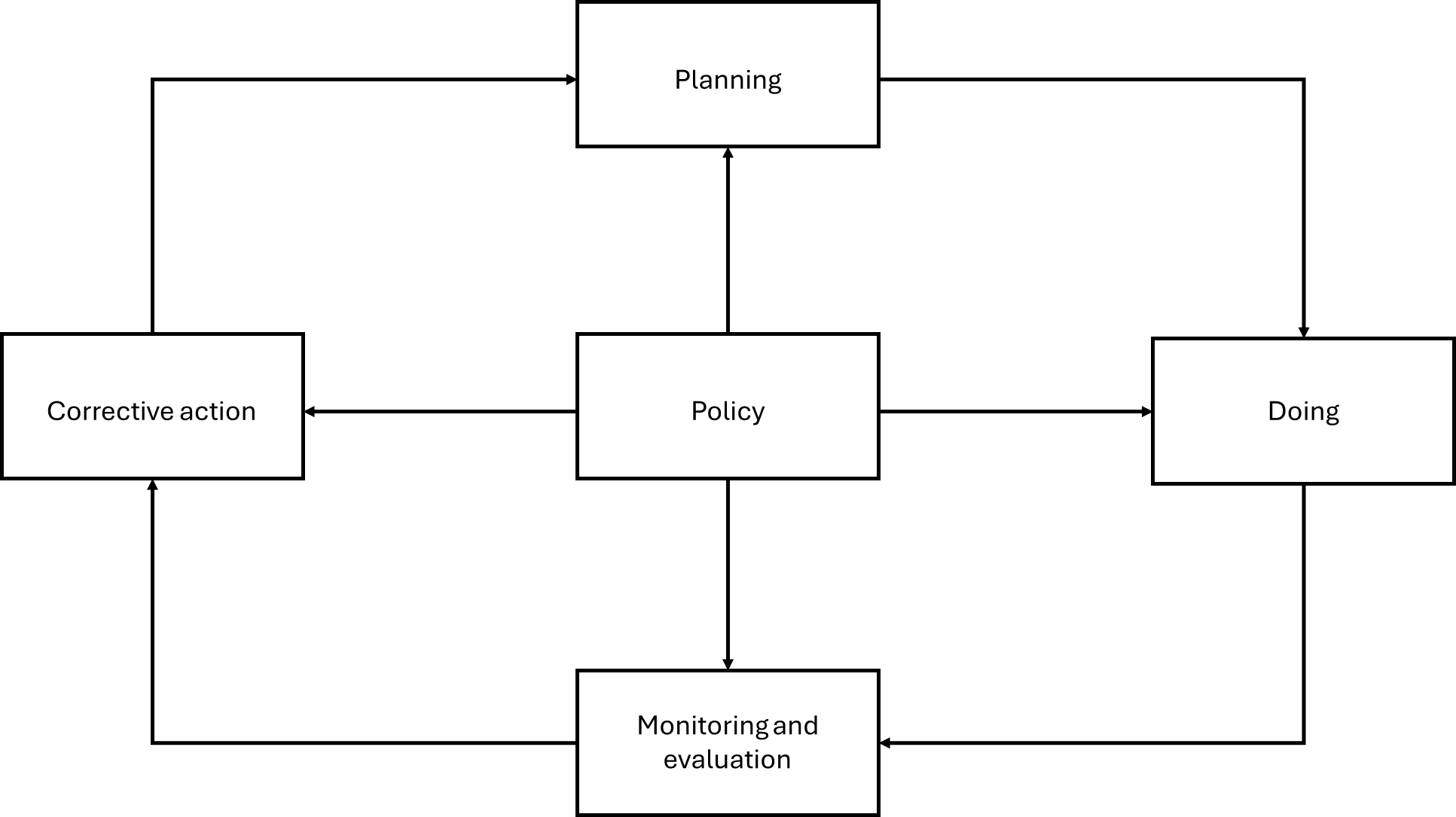

Muslim population in Indonesia was predicted to reach 214 million by 2019, making it a lucrative market from a business perspective. Muslims have the right to obtain and consume halal food products. Food and beverages must be manufactured from raw halal materials and processed in a manner that retains halal status. For instance, shoyu, a Japanese soy sauce widely consumed by Indonesians, traditionally contains a mixture of wheat and soybean fermented in two stages. Non-halal soy sauce may contain brewery or khamr alcohol and pork-derived substances as flavoring ingredients. Therefore, halal assurance system (HAS) 23000 was developed by LPPOM MUI (Food, Drug and Cosmetic Research Institute of Indonesian Ulema Council) and aimed at ensuring a product is free from contamination by haram or najis. HAS development for halal shoyu product line at Kamada Soy Sauce Inc. included conducting a preliminary audit using the gap analysis method. The development was considered complete once all 11 principles of HAS 23000 had been fulfilled. A post-audit was then performed using the same gap analysis method to compare the conditions before and after development. Subsequently, a risk analysis using failure mode and effect analysis (FMEA) was performed based on audit results and brainstorming sessions with the company. Construction of a fishbone diagram was carried out using the calculated risk probability number during FMEA risk analysis.

References

Alserhan BA. Islamic branding: a conceptualization of related terms. Brand Management. 2010;18(1):34-49. https://doi.org/10.1057/bm.2010.18

[BPS] Badan Pusat Statistik. Statistik Indonesia 2019. Jakarta (ID): Badan Pusat Statistik; 2019.

Kamali MH. Tajdid, islah, and civilizational renewal in Islam. Special Issue: Islamic Perspectives on Civilisational Renewal and Reform. 2013;4(4):485-511. https://doi.org/10.52282/icr.v4i4.434

Kataoka S. Functional effects of Japanese fermented soy sauce (shoyu) and its components. Journal of Bioscience and Engineering. 2005;100(3):227-234. https://doi.org/10.1263/jbb.100.227

Lioe HN, Wada K, Aoki T, Yasuda M. Chemical and sensory characteristics of low molecular weight fractions obtained from three types of Japanese soy sauce (shoyu) - koikuchi, tamari, and shiro shoyu. Food Chemistry. 2007;100(4):1669-1677. https://doi.org/10.1016/j.foodchem.2005.12.047

Lioe HN, Selamat J, Yasuda M. Soy sauce and its umami taste: a link from the past to current situation. Journal of Food Science. 2010;75(3):71-76. https://doi.org/10.1111/j.1750-3841.2010.01529.x

[LPPOM MUI] Lembaga Pengkajian Pangan, Obat-obatan dan Kosmetika Majelis Ulama Indonesia. Pedoman untuk Memperoleh Sertifikat Halal. Jakarta (ID): LPPOM MUI; 2005.

[LPPOM MUI] Lembaga Pengkajian Pangan, Obat-obatan dan Kosmetika Majelis Ulama Indonesia. Panduan Penyusunan Sistem Jaminan Halal. Jakarta (ID): LPPOM MUI; 2012.

Marina SJ. Survei implementasi sistem sertifikasi dan labelisasi halal di Indonesia [thesis]. Bogor (ID): Institut Pertanian Bogor; 2003.

McDermott RE, Mikulak RJ, Beauregard MR. The Basics of FMEA 2 Edition. Florida (US): CRC Press; 2009.

Muhandri T, Kadarisman D. Sistem Jaminan Mutu Industri Pangan. Bogor (ID): Institut Pertanian Bogor; 2005.

Murooka Y, Yamashita M. Traditional healthful fermented products of Japan. Journal of Industrial Microbiology and Biotechnology. 2008;35(8):791-798. https://doi.org/10.1007/s10295-008-0362-5

Prabowo S, Rahman AA. Sertifikasi halal sektor industri pengolahan hasil pertanian. Forum Penelitian Agro Ekonomi. 2016;34(1):63. https://doi.org/10.21082/fae.v34n1.2016.57-70

Rahman AA, Abdul M. Establishment of traceability practices through halal assurance system (HAS) implementation. International Journal of Academic Research in Business and Social Sciences. 2017;7(6):130-139. https://doi.org/10.6007/IJARBSS/v7-i6/2951

Riaz MN. Fundamentals of halal foods and certification. Prepared Foods. 2010;179(1):71-76.

Sholichah W, Vanany I, Soeprijanto A, Anwar MK, Fatmawati L. Analisis risiko makanan halal di restoran menggunakan metode failure mode and effect analysis. Jurnal Ilmiah Teknik Industri. 2017;16(1):150-156. https://doi.org/10.23917/jiti.v16i2.4941

Wu TY, Kan MS, Siow LF, Palniandy LK. Effect of temperature on moromi fermentation of soy sauce with intermittent aeration. African Journal of Biotechnology. 2010;9(5):702-706. https://doi.org/10.5897/AJB09.1548

Copyright (c) 2024 Darren Tanaka, Feri Kusnandar, Puspo Edi Giriwono

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.