Optimizing the Use of Recycled Drinking Water Treatment Sludge in Paving Block Production

Abstract

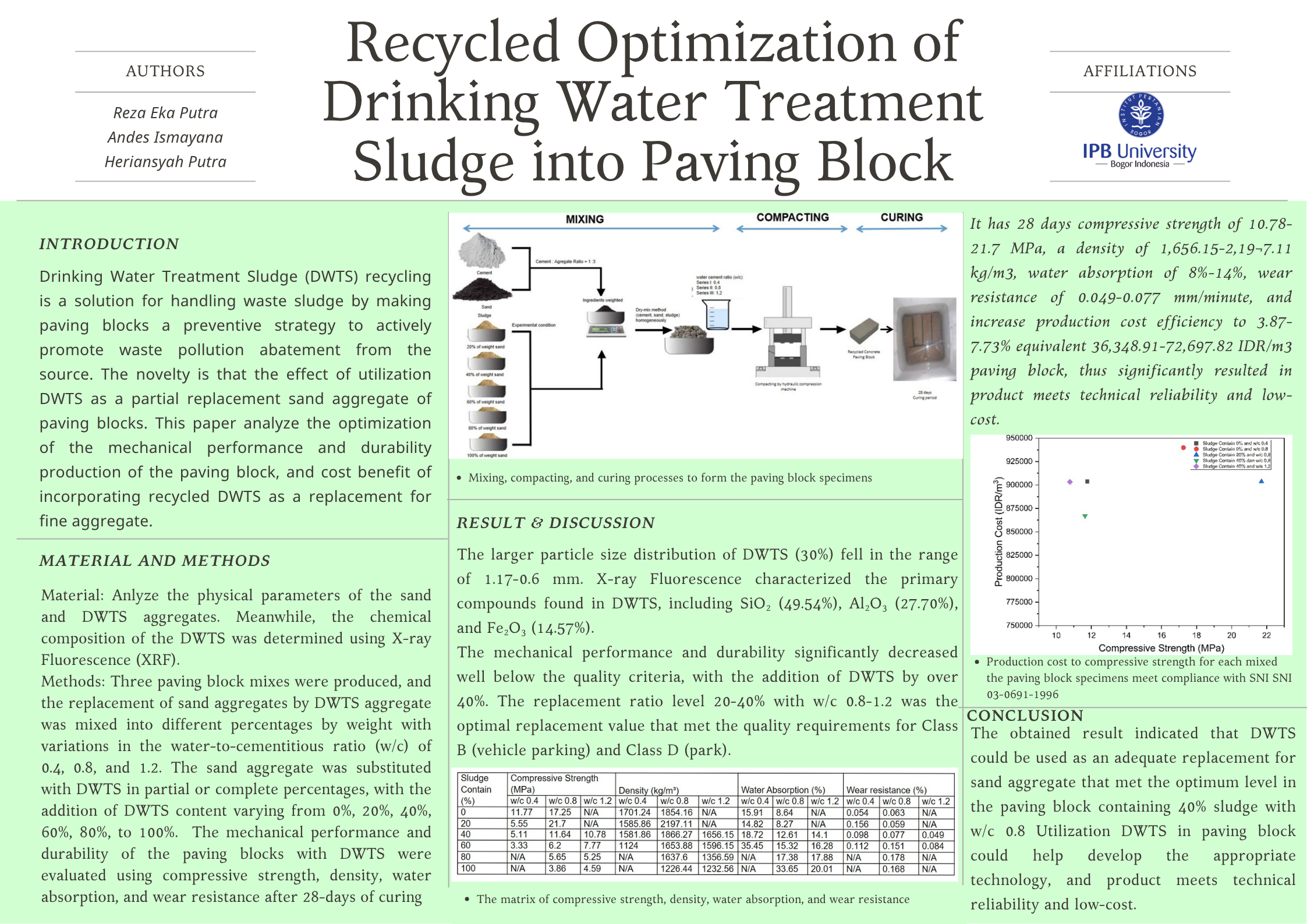

Drinking Water Treatment Sludge (DWTS) recycling is a solution for handling waste sludge by making paving blocks. This paper analysis the optimization of the mechanical performance, durability, and cost production of the paving block incorporating recycled DWTS as a replacement for fine aggregate. Three paving block mixes were produced, and the replacement of sand aggregates by DWTS aggregate was mixed into different percentages by weight with variations in the water-tocementitious ratio (w/c). The mechanical performance and durability significantly decreased, falling well below the quality criteria, with the addition of DWTS increasing by over 40%. The obtained result indicated that DWTS could be used as an adequate replacement for sand aggregate that met the optimum level in the paving block containing 40% sludge with w/c 0.8 could achieve a 28-day compressive strength of 11.64 MPa, a density of 1,866.27 kg/m³, a water absorption of 12.61%, and a wear resistance of 0.077 mm/minute. It was the optimal replacement value that met the quality requirements for Class D (park). It has utilization of DWTS in paving block could help develop the appropriate technology and increase production cost efficiency to 7.73% equivalent 72,697.82 IDR/m3 paving block, thus significantly resulted in product meets technical reliability and low-cost.

Full text article

References

Gastaldini ALG, Hengen MF, Gastaldini MCC, Do Amaral FD, Antolini MB, Coletto T. 2015. The use of water treatment plant sludge ash as a mineral addition. Construction and Building Materials [Internet]. 94:513–520. doi:10.1016/j.conbuildmat.2015.07.038

Ahmad T, Ahmad K, Alam M. 2016. Characterization of Water Treatment Plant’s Sludge and its Safe Disposal Options. Procedia Environmental Sciences. 35:950–955. doi:10.1016/j.proenv.2016.07.088

Liu Y, Zhuge Y, Chow CWK, Keegan A, Li D, Pham PN, Huang J, Siddique R. 2020. Utilization of drinking water treatment sludge in concrete paving blocks: Microstructural analysis, durability and leaching properties. Journal of Environmental Management. 262(March). doi:10.1016/j.jenvman.2020.110352

Sales A, De Souza FR, Almeida FDCR. 2011. Mechanical properties of concrete produced with a composite of water treatment sludge and sawdust. Construction and Building Materials [Internet]. 25(6):2793–2798. doi:10.1016/j.conbuildmat.2010.12.057

Smith KM, Fowler GD, Pullket S, Graham NJD. 2009. Sewage sludge-based adsorbents: A review of their production, properties and use in water treatment applications. Water Research [Internet]. 43(10):2569–2594. doi:10.1016/j.watres.2009.02.038

Wu Y, Du H, Li F, Su H, Bhat SA, Hudori H, Rosadi MY, Arsyad F, Lu Y, Wu H. 2020. Effect of Adding Drinking Water Treatment Sludge on Excess Activated Sludge Digestion Process. Sustainability (Switzerland). 12(17). doi:10.3390/SU12176953

Minh Trang NT, Dao Ho NA, Babel S. 2021. Reuse of waste sludge from water treatment plants and fly ash for manufacturing of adobe bricks. Chemosphere [Internet]. 284(June):131367. doi:10.1016/j.chemosphere.2021.131367

Kluczka J, Zołotajkin M, Ciba J, Staroń M. 2017. Assessment of aluminum bioavailability in alum sludge for agricultural utilization. Environmental Monitoring and Assessment. 189(8). doi:10.1007/s10661-017-6133-x

Yang M, Tan L, Xu Y, Zhao Y, Cheng F, Ye S, Jiang W. 2015. Effect of low pH and aluminum toxicity on the photosynthetic characteristics of different fast-growing Eucalyptus vegetatively propagated clones. PLoS ONE. 10(6):1–15. doi:10.1371/journal.pone.0130963

Grandgirard J, Poinsot D, Krespi L, Nénon JP, Cortesero AM. 2002. Costs of secondary parasitism in the facultative hyperparasitoid Pachycrepoideus dubius: Does host size matter? Entomologia Experimentalis et Applicata. 103(3):239–248. doi:10.1023/A

Tošić N, Marinković S, Dašić T, Stanić M. 2015. Multicriteria optimization of natural and recycled aggregate concrete for structural use. Journal of Cleaner Production. 87(1):766–776. doi:10.1016/j.jclepro.2014.10.070

Pan D, Yaseen SA, Chen K, Niu D, Ying Leung CK, Li Z. 2021. Study of the influence of seawater and sea sand on the mechanical and microstructural properties of concrete. Journal of Building Engineering. 42(April). doi:10.1016/j.jobe.2021.103006

Tam VWY, Soomro M, Evangelista ACJ. 2018. A review of recycled aggregate in concrete applications (2000–2017). Construction and Building Materials [Internet]. 172:272–292. doi:10.1016/j.conbuildmat.2018.03.240

Gao DY, Lv M, Yang L, Tang J, Chen G, Meng Y. 2020. Experimental study of utilizing recycled fine aggregate for the preparation of high ductility cementitious composites. Materials. 13(3):8–12. doi:10.3390/ma13030679

Nedeljković M, Visser J, Šavija B, Valcke S, Schlangen E. 2021. Use of fine recycled concrete aggregates in concrete: A critical review. Journal of Building Engineering. 38(May 2020). doi:10.1016/j.jobe.2021.102196

Yeo JS, Koting S, Onn CC, Mo KH. 2021. An overview on the properties of eco-friendly concrete paving blocks incorporating selected waste materials as aggregate. Environmental Science and Pollution Research.(Gagg 2014). doi:10.1007/s11356-021-13836-3

Dinh HL, Liu J, Ong DEL, Doh JH. 2022. A sustainable solution to excessive river sand mining by utilizing by-products in concrete manufacturing: A state-of-the-art review. Cleaner Materials. 6(September):100140. doi:10.1016/j.clema.2022.100140

Sims I. 1986. Sand, gravel and crushed rock aggregates for contruction purposes. Quarterly Journal of Engineering Geology. 19:325-338. https://doi.org/10.1144/GSL.QJEG.1986.019.03.13

Boyd SE, Limpenny DS, Rees HL, Cooper KM. 2005. The effects of marine sand and gravel extraction on the macrobenthos at a commercial dredging site (results 6 years post-dredging). ICES Journal of Marine Science. 62(2):145–162. doi:10.1016/j.icesjms.2004.11.014

Chauhan SS. 2010. Mining, Development and Environment: A Case Study of Bijolia Mining Area in Rajasthan, India. Journal of Human Ecology. 31(1):65–72. doi:10.1080/09709274.2010.11906299

Sjögren B. 2001. Re: Lung cancer among industrial sand workers exposed to crystalline silica. American Journal of Epidemiology. 154(8):785. doi:10.1093/aje/154.8.785

Sairanen M, Rinne M. 2019. Dust emission from crushing of hard rock aggregates. Atmospheric Pollution Research. 10(2):656–664. doi:10.1016/j.apr.2018.11.007

Habert G, Roussel N. 2009. Study of two concrete mix-design strategies to reach carbon mitigation objectives. Cement and Concrete Composites [Internet]. 31(6):397–402. doi:10.1016/j.cemconcomp.2009.04.001

United Nations. 2015. Transforming our world: the 2030 agenda for sustainable development. United Nations.https://sustainabledevelopment.un.org/content/documents/21252030%20Agenda%20for%20Sustainable%20Development%20web.pdf

Rodríguez NH, Ramírez SM, Varela MTB, Guillem M, Puig J, Larrotcha E, Flores J. 2010. Re-use of drinking water treatment plant (DWTP) sludge: Characterization and technological behaviour of cement mortars with atomized sludge additions. Cement and Concrete Research [Internet]. 40(5):778–786. doi:10.1016/j.cemconres.2009.11.012

Ramirez Zamora RM, Ceron Alfaro O, Cabirol N, Espejel Ayala F, Duran Moreno A. 2008. Valorization of drinking water treatment sludges as raw materials to produce concrete and mortar. American Journal of Environmental Sciences. 4(3):223–228. doi:10.3844/ajessp.2008.223.228

Huang CH, Wang SY. 2013. Application of water treatment sludge in the manufacturing of lightweight aggregate. Construction and Building Materials [Internet]. 43:174–183. doi:10.1016/j.conbuildmat.2013.02.016

Hasiany S, Noor E, Yani M. 2015. The Implementation Cleaner Production to Manage ProducedWater in thePetroleum Industry. Journal Natural Resources and Environmental Management. 5(1):25–32. doi: 10.29244/jpsl.5.1.25 (in Bahasa)

Tataranni P. 2019. Recycled waste powders for alkali-activated paving blocks for urban pavements: A full laboratory characterization. Infrastructures. 4(4). doi:10.3390/infrastructures4040073

Cabrera M, Galvín AP, Agrela F. 2018. Leaching issues in recycled aggregate concrete. New Trends in Eco-efficient and Recycled Concrete.:329–356. doi:10.1016/B978-0-08-102480-5.00012-9

Containing A, Sludge M. 2020. Properties of Concrete with Recycled Concrete Aggregate Containing Metallurgical Sludge Waste.

. Liu Y, Zhuge Y, Chow CWK, Keegan A, Pham PN, Li D, Qian G, Wang L. 2020. Recycling drinking water treatment sludge into eco-concrete blocks with CO2 curing: Durability and leachability. Science of the Total Environment [Internet]. 746:141182. doi:10.1016/j.scitotenv.2020.141182

Tantawy MA. 2015. Characterization and pozzolanic properties of calcined alum sludge. Materials Research Bulletin [Internet]. 61:415–421. doi:10.1016/j.materresbull.2014.10.042

Hidalgo AM, Murcia MD, Gómez M, Gómez E, García-Izquierdo C, Solano C. 2017. Possible Uses for Sludge from Drinking Water Treatment Plants. Journal of Environmental Engineering. 143(3):1–7. doi:10.1061/(asce)ee.1943-7870.0001176

Wang L, Zou F, Fang X, Tsang DCW, Poon CS, Leng Z, Baek K. 2018. A novel type of controlled low strength material derived from alum sludge and green materials. Construction and Building Materials [Internet]. 165:792–800. doi:10.1016/j.conbuildmat.2018.01.078

Tay J-H, Show K-Y, Hong S-Y. 2002. Concrete Aggregates Made from Sludge-Marine Clay Mixes. Journal of Materials in Civil Engineering. 14(5):392–398. doi:10.1061/(asce)0899-1561(2002)14:5(392)

SNI 15-2049. 2004. Portland Cement Composite. Indonesian National Standard. (in Bahasa)

Djamaluddin AR, Caronge MA, Tjaronge MW, Lando AT, Irmawaty R. 2020. Evaluation of sustainable concrete paving blocks incorporating processed waste tea ash. Case Studies in Construction Materials. 12. doi:10.1016/j.cscm.2019.e00325

Atoyebi OD, Ikubanni PP, Adesina A, Araoye OV, Davies EEI. 2020. Effect of curing methods on the strength of interlocking paving blocks. Cogent Engineering. 7:1. 1770914. doi:10.1080/23311916.2020.1770914

ASTM C140. 2022. Standard test metods for sampling and tensting oncrete masonary unit and related units. The American Society for Testing and Materials. 1–24. doi:10.1520/C0140

SNI 03-0691-1996. 1996. Paving Block. Indonesia National Standard (in Bahasa)

Pei Y, Tham R, Lim S, Fahim M, Ooi C, Krishnan P, Matsumoto A, Yeoh F. 2017. Applied Clay Science Evaluation and reutilization of water sludge from fresh water processing plant as a green clay substituent. Applied Clay Science [Internet]. 143(December 2016):300–306. doi:10.1016/j.clay.2017.04.007

SNI 1970:2008. 2008. Standard method for specific gravity and watar absorption of fine aggregates. Indonesia National Standard (in Bahasa)

SNI 03-4804-1998. 1998. Standard method for bulk density and air cavities of aggregate. Indonesia National Standard (in Bahasa)

SNI 03-1968-1990. 1990. Standard method for sieve analysis of fine and coarse aggregate. Indonesia National Standard (in Bahasa)

Tony MA. 2022. Valorization of undervalued aluminum ‑ based waterworks sludge waste for the science of “ The 5 Rs ’ criteria ”. Applied Water Science [Internet]. 12(2):1–30. doi:10.1007/s13201-021-01554-7

Song X, Pan Y, Wu Q, Cheng Z, Ma W. 2011. Phosphate removal from aqueous solutions by adsorption using ferric sludge. DES [Internet]. 280(1–3):384–390. doi:10.1016/j.desal.2011.07.028

Mavroulidou M, Feruku B, Boulouki G. 2022. Properties of structural concrete with high-strength cement mixes containing waste paper sludge ash. Journal of Material Cycles and Waste Management [Internet]. 24(4):1317–1332. doi:10.1007/s10163-022-01402-z

Kaish ABMA, Chimuanya T, Zakaria I, Mohsen M, Nahar L. 2021. Properties of concrete incorporating alum sludge in different conditions as partial replacement of fine aggregate. Construction and Building Materials [Internet]. 284:122669. doi:10.1016/j.conbuildmat.2021.122669

Yu C, Sun W, Scrivener K. 2013. Cement and Concrete Research. Cement and Concrete Research [Internet]. 43:105–111. doi:10.1016/j.cemconres.2012.10.001

Pham PN, Duan W, Zhuge Y, Liu Y, Tormo IES. 2021. Properties of mortar incorporating untreated and treated drinking water treatment sludge. Construction and Building Materials [Internet]. 280:122558. doi:10.1016/j.conbuildmat.2021.122558

Poon CS, Shui ZH, Lam L, Fok H, Kou SC. 2004. Influence of moisture states of natural and recycled aggregates on the slump and compressive strength of concrete. Cement and Concrete Research. 34(1):31–36. doi:10.1016/S0008-8846(03)00186-8

Gheisari K, Javadpour S, Oh JT, Ghaffari M. 2009. The effect of milling speed on the structural properties of mechanically alloyed Fe-45%Ni powders. Journal of Alloys and Compounds. 472(1–2):416–420. doi:10.1016/j.jallcom.2008.04.074

Mayooran S, Ragavan S, Sathiparan N. 2017. Comparative study on open air burnt low- and high-carbon rice husk ash as partial cement replacement in cement block production. Journal of Building Engineering [Internet]. 13:137–145. doi:10.1016/j.jobe.2017.07.011

Gencel O, Ozel C, Koksal F, Erdogmus E, Martínez-Barrera G, Brostow W. 2012. Properties of concrete paving blocks made with waste marble. Journal of Cleaner Production [Internet]. 21(1):62–70. doi:10.1016/j.jclepro.2011.08.023

Tallon C, Limacher M, Franks G V. 2010. Effect of particle size on the shaping of ceramics by slip casting. Journal of the European Ceramic Society. 30(14):2819–2826. doi:10.1016/j.jeurceramsoc.2010.03.019

Benlalla A, Elmoussaouiti M, Dahhou M, Assa M. 2015. Applied Clay Science Utilization of water treatment plant sludge in structural ceramics bricks. 118:171–177. doi:10.1016/j.clay.2015.09.012

Ghafoori N, Mathis R. 1998. Prediction of freezing and thawing durability of concrete paving. ASCE. (February):45–51. doi: 10.1061/(ASCE)0899-1561(1998)10:1(45)

Liu Y, Zhuge Y, Chow CWK, Keegan A, Li D, Pham PN, Huang J, Siddique R. 2020. Properties and microstructure of concrete blocks incorporating drinking water treatment sludge exposed to early-age carbonation curing. Journal of Cleaner Production [Internet]. 261:121257. doi:10.1016/j.jclepro.2020.121257

Limami H, Manssouri I, Cherkaoui K, Khaldoun A. 2021. Recycled wastewater treatment plant sludge as a construction material additive to ecological lightweight earth bricks. Cleaner Engineering and Technology [Internet]. 2(January):100050. doi:10.1016/j.clet.2021.100050

de Oliveira Andrade JJ, Wenzel MC, da Rocha GH, da Silva SR. 2018. Performance of rendering mortars containing sludge from water treatment plants as fine recycled aggregate. Journal of Cleaner Production. 192:159–168. doi:10.1016/j.jclepro.2018.04.246

López Gayarre F, López-Colina C, Serrano MA, López-Martínez A. 2013. Manufacture of concrete kerbs and floor blocks with recycled aggregate from C&DW. Construction and Building Materials. 40:1193–1199. doi:10.1016/j.conbuildmat.2011.11.040

Kizinievič O, Kizinievič V. 2017. Utilisation of drinking water treatment sludge for the manufacturing of ceramic products. IOP Conference Series: Materials Science and Engineering. 251(1). doi:10.1088/1757-899X/251/1/012018

Rucińska T, Głowacka A, Sidełko R. 2021. The influence of incinerated sewage sludge as an aggregate on the selected properties of cement mortars. Materials. 14(19):1–14. doi:10.3390/ma14195846

Sadek DM, El-Attar MM, Ali AM. 2017. Physico-mechanical and durability characteristics of concrete paving blocks incorporating cement kiln dust. Construction and Building Materials [Internet]. 157:300–312. doi:10.1016/j.conbuildmat.2017.09.107

Sansalone J, Kuang X, Ranieri V. 2008. Permeable Pavement as a Hydraulic and Filtration Interface for Urban Drainage. Journal of Irrigation and Drainage Engineering. 134(5):666–674. doi:10.1061/(asce)0733-9437(2008)134:5(666)

Buyung NR, Ghani ANA, Abdullah NH. 2021. Properties Of Porous Paver Concrete Blocks And Their Overall Infiltration Rate In Pavement Formation. International Journal of GEOMATE. 21(86):32–39. doi:10.21660/2021.86.j2249

Authors

Authors who publish with this journal agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgement of its initial publication in this journal.

- Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See The Effect of Open Access).