The Addition of Calcium Carbonate (CaCO3) from Anadara granosa and Glycerol on The Quality of Bioplastic

Abstract

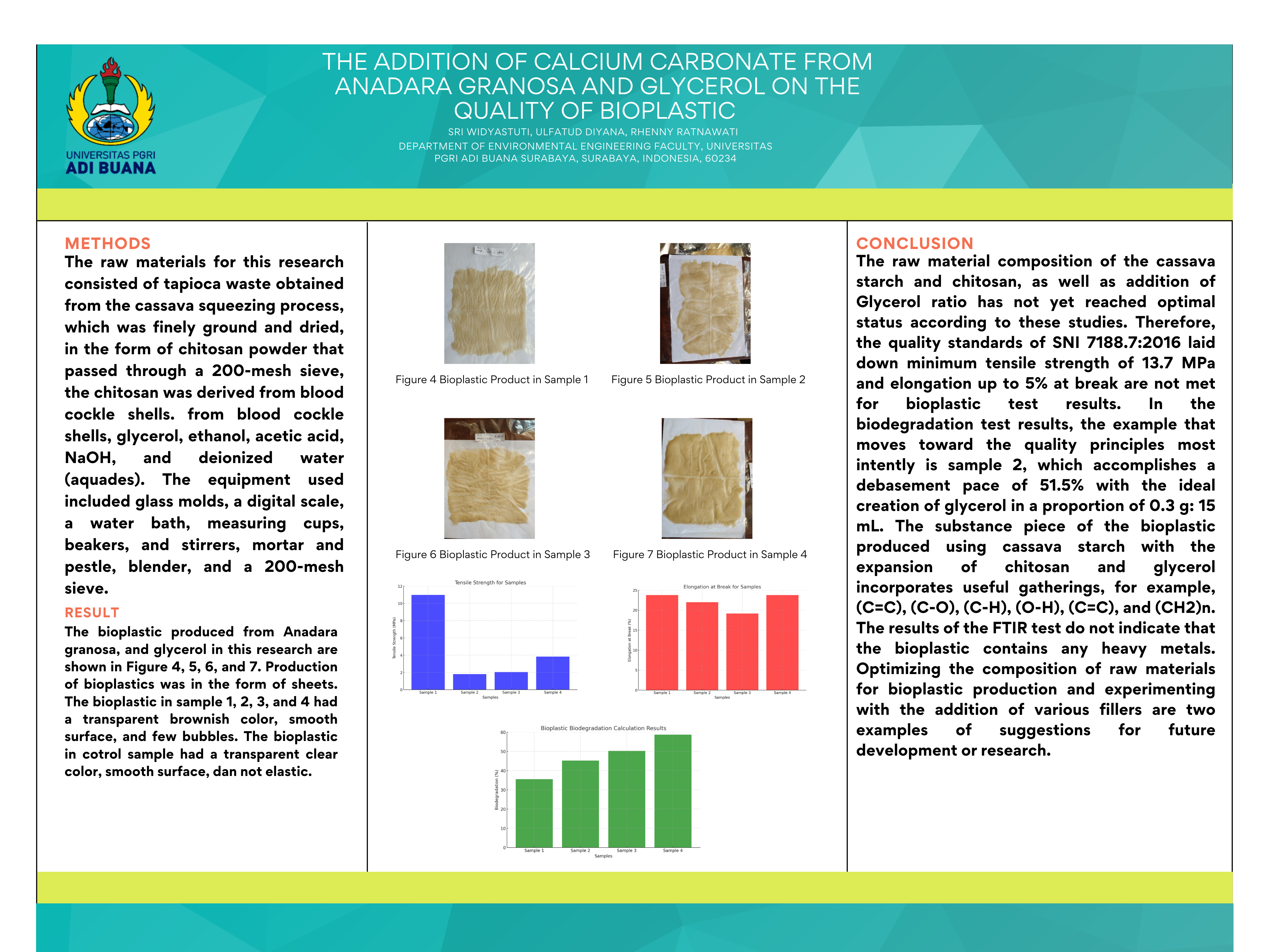

Bioplastic material is derived from natural materials that microorganisms can break down producing water and carbon dioxide. With the expansion of chitosan, CaCO3 from Anadara granosa and glycerol, the structure of the materials utilized to create bioplastics from custard squander. The technique utilized was a trial, which started with producing chitosan and CaCO3 from Andara granosa. The production of bioplastics was completed with custard squander composites blended in with Anadara granosa with an organization of 80% : 20% with the expansion of CaCO3 and glycerol. The ratio of CaCO3 and glycerol differed into four creation proportions 0.3 g : 10 mL; 0.3 g : 15 mL; 0.4 g : 10mL; 0.4 g : 15 mL. Tensile strength upsides of tests 1 10.98 MPa. The elongation test values are sample 1 23.79%, sample 2 22.00%, sample 3 19.16%, and sample 4 23.80%. In the after effects of biodegradation tests with soil media, the worth is near sample 2 which can be evaluated by 51.5% with an ideal structure of the proportion of CaCO3 and glycerol 0.3 g : 15 mL.

References

[2] Jethoo AS. Effect of Fiber Reinforcement on Tensile Strength and Flexibility of Corn Starch-Based Bioplastic. IOP Conference Series: Materials Science and Engineering. 2019;652(1):1–5. doi:10.1088/1757-899X/652/1/012035

[3] Muhammad A, Roslan A, Sanusi SNA, Shahimi MQ, Nazari NZ. Mechanical Properties of Bioplastic form Cellulose Nanocrystal (CNC) Mangosteen Peel Using Glycerol as Plasticizer. Journal of Physics: Conference Series. 2019;1349(1):1–8. doi:10.1088/1742-6596/1349/1/012099

[4] Hidayat F, Syaubari S, Salima R. Utilization of Tapioca Starch and Chitosan in Production of Biodegradable Plastic with The Addition of Glycerol as Plasticizer. Jurnal Litbang Industri. 2020;10(1):33–38. doi:10.24960/jli.v10i1.5970.33-38

[5] Xia Q, Chen C, Yao Y, Li J, He S, Zhou Y, Li T, Pan X, Yao Y, Hu L. A Strong, Biodegradable and Recyclable Lignocellulosic Bioplastic. Nature Sustainability. 2021;4(7):627–635. doi:10.1038/s41893-021-00702-w

[6] Sari NI, Syahrir M, Pratiwi DE. Effect of Addition of Chitosan and CaCO3 Filler on Bioplastic Characteristics of Gadung-Yam (Dioscorea hispida Dennst). Chemica: Jurnal Ilmiah Kimia dan Pendidikan Kimia. 2022;23(1):78–89. doi:10.35580/chemica.v23i1.33919

[7] Udyani K. Utilization of Waste Shell Skin and Sweet Starter for Bioplastic Manufacturing. Seminar Nasional Sains dan Teknologi Terapan. 2017;5(100):167–174.

[8] Rahim A, Musta R. Pengaruh Penambahan Tepung Tapioka Pada Pati Ubi Kayu (Manihot esculenta) Terhadap Pembuatan Plastik Biodegradable dan Karakterisasinya. IJCA (Indonesian Journal of Chemical Analysis). 2019;2(2):66–73. doi:10.20885/ijca.vol2.iss2.art4

[9] Kamsiati E, Herawati H, Purwani EY. The Development Potential of Sago and Cassava Starch-Based Biodegradable Plastic in Indonesia. Jurnal Penelitian dan Pengembangan Pertanian. 2017;36(2):67–76. doi:10.21082/jp3.v36n2.2017.p67-76

[10] Nasution H, Julianti E, Dalimunthe NF, Wulandari G. The Role of Betel (Piper betle) Leaf Extract and Glycerol on Physical Properties of Bioplastic Based on Sago Starch. IOP Conference Series: Earth and Environmental Science. 2021;912(1):1–7. doi:10.1088/1755-1315/912/1/012042

[11] Kirboga S, Öner M. The Properties of PHBV/CaCO3 Composites Prepared by Melt Processing. In: 6th International Conference on New Trends in Chemistry. Istanbul; 2020. p. 102–103.

[12] Widyastuti S, Ratnawati R, Slyviana N, Priyono. Production of Bioplastics from Organic Waste with Tapioca Flour and Glycerol. Journal of Natural Resources and Environmental Management. 2021;11(4):677–684. doi:10.29244/jpsl.11.4.677-684

[13] Ratnawati R, Widyastuti S, Utomo Y, Evawati D. Addition of Anadara Granosa Shell Chitosan in Production Bioplastics. Jurnal Pengelolaan Sumberdaya Alam dan Lingkungan (Journal of Natural Resources and Environmental Management). 2023;13(2):175–185. doi:10.29244/jpsl.13.2.175-185

[14] Nasir NN, Othman SA. The Physical and Mechanical Properties of Corn-based Bioplastic Films with Different Starch and Glycerol Content. Journal of Physical Science. 2021;32(3):89–101. doi:10.21315/jps2021.32.3.7

[15] Hendrawan Y, Putranto AW, Fauziah TR, Argo BD. Modeling and Optimization of Tensile Strength of Arrowroot Bioplastic Using Response Surface Method. IOP Conference Series: Earth and Environmental Science. 2020;515(1):1–7. doi:10.1088/1755-1315/515/1/012079

[16] Pranata A, Nasution H, Harahap H, Yustira A. The Effect Solvent Type on Natural Fiber Immersion Process on Tensile Strength of Cellulose-Based Bioplastic. IOP Conference Series: Earth and Environmental Science. 2021;912(1):1–5. doi:10.1088/1755-1315/912/1/012062

[17] Nandiyanto ABD, Fiandini M, Ragadhita R, Sukmafitri A, Salam H, Triawan F. Mechanical and Biodegradation Properties of Cornstarch-Based Bioplastic Material. Materials Physics and Mechanics. 2020;44(3):380–391. doi:10.18720/MPM.4432020_9

[18] Widodo LU, Wati SN, Vivi A.P NM. Making Edible Film From Yellow Pumpkin and Chitosan With Glycerol as Plasticizer. Jurnal Teknologi Pangan. 2019;13(1):59–65. doi:10.33005/jtp.v13i1.1511

[19] Fauziyah SN, Mubarak AS, Pujiastuti DY. Application of Glycerol on Bioplastic based Carrageenan Waste Cellulose on Biodegradability and Mechanical Properties Bioplastic. IOP Conference Series: Earth and Environmental Science. 2021;679(1):1–5. doi:10.1088/1755-1315/679/1/012005

[20] Nuriyah L, Saroja G, Rohmad J. The Effect of Calcium Carbonate Addition to Mechanical Properties of Bioplastic Made from Cassava Starch with Glycerol as Plasticizer. IOP Conference Series: Materials Science and Engineering. 2019;546(4):1–5. doi:10.1088/1757-899X/546/4/042030

[21] Peng X, Dong K, Zhang Y, Wang L, Wei C, Lv T, Wang ZL, Wu Z. Sweat-Permeable, Biodegradable, Transparent and Self-powered Chitosan-Based Electronic Skin with Ultrathin Elastic Gold Nanofibers. Advanced Functional Materials. 2022;32(20):1–10. doi:10.1002/adfm.202112241

[22] SNI 7188.7:2016. Kriteria ekolabel - Bagian 7: Kategori produk tas belanja plastik dan bioplastik mudah terurai (SNI 7188.7:2016). 2016.

[23] Agustin YE, Padmawijaya KS. Effect of Glycerol and Zinc Oxide Addition on Antibacterial Activity of Biodegradable Bioplastics from Chitosan-Kepok Banana Peel Starch. IOP Conference Series: Materials Science and Engineering. 2017;223(1):1–7. doi:10.1088/1757-899X/223/1/012046

[24] Triawan F, Nandiyanto ABD, Suryani IO, Fiandini M, Budiman BA. The Influence of Turmeric Microparticles Amount on The Mechanical and Biodegradation Properties of Cornstarch-Based Bioplastic Material: From Bioplastic Literature Review to Experiments. Materials Physics and Mechanics. 2020;46(1):99–114. doi:10.18149/MPM.4612020_10

[25] Shafqat A, Tahir A, Khan WU, Mahmood A, Abbasi GH. Production and Characterization of Rice Starch and Corn Starch Based Biodegradable Bioplastic Using Various Plasticizers and Natural Reinforcing Fillers Arifa. Cellulose Chemistry and Technology. 2021;55:1–15.

[26] Lestari RAS, Kasmiyatun M, Dermawan K, Aini AN, Riyati N, Putri FR. Bioplastic from Jackfruit Seeds and Rice. IOP Conference Series: Materials Science and Engineering. 2020;835(1):1–10. doi:10.1088/1757-899X/835/1/012035

[27] Saleh ERM, Utami S. Characteristics of Biodegradable Plastic from Mulu Bebe Banana Peel Starch with The Addition of Chitosan and Glycerol Plasticizer. IOP Conference Series: Earth and Environmental Science. 2023;1177(1):1–12. doi:10.1088/1755-1315/1177/1/012047

[28] Yaradaddi JS, Banapurmath NR, Ganachari S V., Saudagar MEM, Sajjan AM, Kamat S, Mutjaba MA, Shettar AS, Anqi AE, Safaei MR, et al. Bio-based material from fruit waste of orange peel for industrial applications | Elsevier Enhanced Reader. Journal of Materials Research and Technology. 2022;17:3186–3197. https://reader.elsevier.com/reader/sd/pii/S2238785421009972?token=51D4FDE397C061970D3E04EC8EB6475A854F504B498A776CDD1623BFF098FDFE421EC248E17473B4AF1A4E14DF600356&originRegion=eu-west-1&originCreation=20210930012842

[29] Maneking E, Sangian HF, Tongkukut SHJ. Production and Characterization of Biomass-Based Bioplastics with Glycerol Plasticizer. Jurnal MIPA. 2020;9(1):23–27.

[30] Abidin NDZ, Azhar NS, Sarip MN, Hamid HA, Nasir NAHA. Production of Bioplastic from Cassava Peel with Different Concentrations of Glycerol and CaCO3 as Filler. AIP Conference Proceedings. 2021;2332(1):1–8. doi:10.1063/5.0043482

Authors

This work is licensed under a Creative Commons Attribution 4.0 International License.

Authors who publish with this journal agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgement of its initial publication in this journal.

- Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See The Effect of Open Access).