Analysis of Temperature and Airflow Distribution during Carrot Drying Using a Tray Dryer Based on CFD Simulation

DOI:

https://doi.org/10.19028/jtep.013.4.529-545Keywords:

ANSYS Fluent, Pengeringan, Perpindahan Panas, Suhu dan ThermodinamikaAbstract

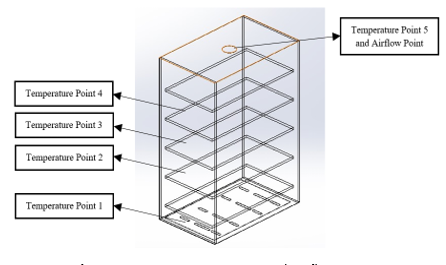

Carrot (Daucus carota L.) is a highly nutritious vegetable that is prone to spoilage due to its high moisture content. Drying is an effective method to extend its shelf life, with the tray dryer being one of the commonly used technologies. However, the efficiency of the drying process greatly depends on the uniformity of temperature and airflow distribution within the drying chamber. This study aims to analyze the distribution of temperature and airflow inside a tray dryer using Computational Fluid Dynamics (CFD) during the drying of carrots. Simulations were conducted at three different temperatures (50°C, 60°C, and 70°C) and two air velocities (2 m/s and 3 m/s) using SolidWorks, ANSYS Fluent, and Origin software. The simulation results showed that both temperature and airflow were unevenly distributed, particularly in the middle and upper sections of the dryer. This non-uniformity can lead to inconsistent drying and reduced product quality. Validation was carried out by comparing simulation results with experimental measurements using relative error analysis. The error values obtained ranged from 1.41% to 3.82% for temperature and 0.5% to 2.41% for air velocity, all below 4%. These results indicate that the CFD model is sufficiently accurate and can be applied to support the design and optimization of more efficient drying equipment.

Downloads

Downloads

Published

Issue

Section

License

Copyright (c) 2025 Jurnal Keteknikan Pertanian

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

Authors submitting manuscripts should understand and agree that copyright of manuscripts of the article shall be assigned/transferred to Jurnal Keteknikan Pertanian. This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License (CC BY-SA) where Authors and Readers can copy and redistribute the material in any medium or format, as well as remix, transform, and build upon the material for any purpose, but they must give appropriate credit (cite to the article or content), provide a link to the license, and indicate if changes were made. If you remix, transform, or build upon the material, you must distribute your contributions under the same license as the original.