Time Study Analysis on Rice Milling Process at Rice Milling Unit (RMU) “Teaching Industry” Unsoed

DOI:

https://doi.org/10.19028/jtep.013.2.211-226Keywords:

rice milling unit, standard time, time study, work elementsAbstract

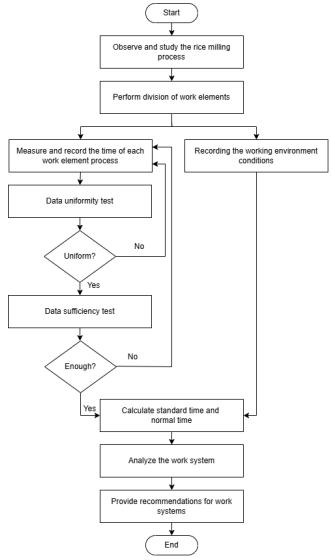

Rice is a major food crop in Indonesia that requires special attention in the milling process to ensure efficiency of working time. This study aims to identify the division of work elements in the rice milling process, determine the standard time used by operators, and provide recommendations for improving the work system in the Unsoed “Teaching Industry”. Research data were collected by measuring the time of each work element in the rice milling process using a stopwatch. The work elements are divided into two groups: rice milling elements and rice packaging elements. The analysis methods used include data adequacy and uniformity tests as well as calculations of standard time and normal time. The results of the analysis show that the standard time for the rice milling process is 5,920.55 seconds per 100 kg of rice, while the standard time for the rice packaging process reaches 27,549.81 seconds per 100 kg of rice. The time required is still relatively long compared to previous studies, so several improvements are recommended, including eliminating unnecessary work elements, carrying out thorough maintenance of the tools in the RMU, and placing a bucket in the outlet hole when changing sacks to reduce the time to collect scattered rice. In addition, in the rice packaging process, the element of rice sorting can be eliminated. Other recommendations include improving the working environment by encouraging workers to wear masks during the rice milling process.

Downloads

Downloads

Published

Issue

Section

License

Authors submitting manuscripts should understand and agree that copyright of manuscripts of the article shall be assigned/transferred to Jurnal Keteknikan Pertanian. This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License (CC BY-SA) where Authors and Readers can copy and redistribute the material in any medium or format, as well as remix, transform, and build upon the material for any purpose, but they must give appropriate credit (cite to the article or content), provide a link to the license, and indicate if changes were made. If you remix, transform, or build upon the material, you must distribute your contributions under the same license as the original.