Effect of Pulsed-Spray Time Variations with Water Coolant in Cooling Media on Solar Panel Efficiency and Temperature

DOI:

https://doi.org/10.19028/jtep.013.1.18-38Keywords:

Energi efficiency, solar panel, cooling; water coolant, water spray coolingAbstract

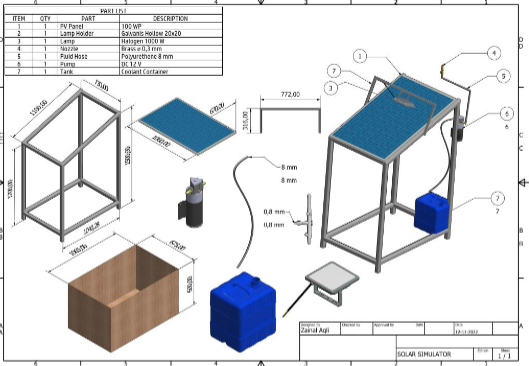

Solar panel technology enables the conversion of sunlight into electrical energy. However, some problems can arise with the performance of solar panels, for example, increasing the temperature of the solar panels beyond their working limits. Increasing temperatures will reduce the performance of solar panels. So, it is essential to maintain the temperature of the solar panels so that their performance remains optimal. This research was conducted to determine the effect of delayed timing of the back and front surfaces of spray cooling on average temperature, output power, and solar panel energy optimization. This experimental test can reduce the temperature of solar panels at a spray delay time of 10 minutes to 58.95°C, at a spray delay time of 20 minutes to 70.78°C, and at a spray delay time of 30 minutes to 78.63 °C. The cooling method is carried out for 1 minute with varying spray delay times of 10, 20, and 30 min. Through this test, the total energy value is also obtained. Suppose the spray delay time is 10, 20 and 30 min, respectively, 5.60 x 10-3 kWh (20150.78 Joules), 5.27 x 10-3 kWh (1897.,11 Joules) and 5.11 x 10-3 kWh (18383.68 Joules). The conclusion from the research that has been carried out is that the most optimal delay time is a delay time of 10 minutes with an average temperature of 58.95°C, and the best energy optimization is with a total energy of 20150.78 Joules or 5.27 x 10-3 kWh.

Downloads

Downloads

Published

Issue

Section

License

Authors submitting manuscripts should understand and agree that copyright of manuscripts of the article shall be assigned/transferred to Jurnal Keteknikan Pertanian. This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License (CC BY-SA) where Authors and Readers can copy and redistribute the material in any medium or format, as well as remix, transform, and build upon the material for any purpose, but they must give appropriate credit (cite to the article or content), provide a link to the license, and indicate if changes were made. If you remix, transform, or build upon the material, you must distribute your contributions under the same license as the original.