The Potential of Adsorption Technology for Batik Wastewater Treatment: A Review

Abstract

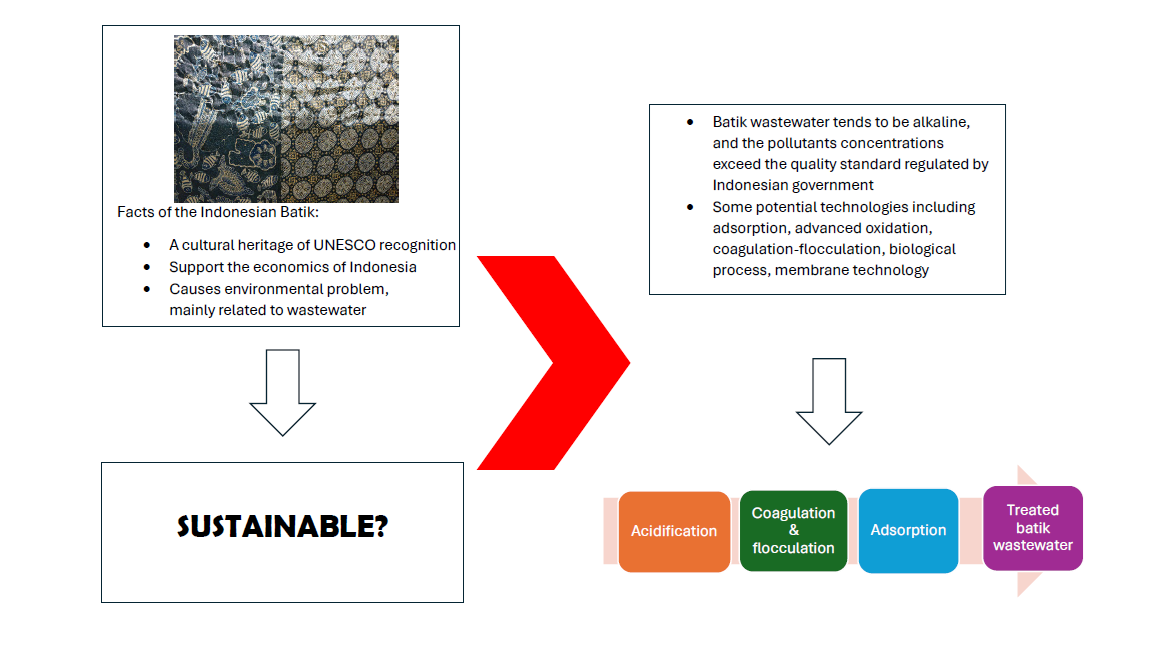

The Indonesian batik plays a crucial role in supporting the country's economy. However, its production often leads to environmental problems. As sustainable development implies the need for economic benefits equally accessible by all people without compromising the environment for the future of the next generation, the sustainability of batik means that batik, as a cultural product, should be preserved, and its production can bring economic benefits without harming the environment. Therefore, environmental issues related to batik should be overcome. Studies addressing the problem of batik wastewater have been conducted; however, adsorption technology is gaining popularity due to the benefits it offers. This review examines the characteristics of batik wastewater, identifies existing batik wastewater treatment technologies, and evaluates the potential of adsorption technology for batik wastewater treatment. This literature review was conducted using Science Direct and Directory of Open Access Journals (DOAJ) search engines, which initially collected 78 articles, and finally, 58 articles were found to be suitable for the review. An Excel-based matrix was then created to analyze the literature manually. It is found that batik wastewater is usually alkaline; the Biological Oxygen Demand (BOD), Chemical Oxygen Demand (COD), and Total Suspended Solids (TSS) usually exceed the quality standard regulated by the Indonesian government, and are usually non-biodegradable, as indicated by the low BOD/COD ratio. Adsorption is widely applied, economically feasible, and can be easily operated by batik entrepreneurs. The performance of this technology is best when combined with other processes.

Full text article

References

2. Kusumawati, N; Rahmadyanti, E; Sianita, M.M. Batik became two sides of blade for the sustainable development in Indonesia. in: Sharma SK (Ed.). Green Chemistry and Water Remediation: Research and Applications, Elsevier. 2021, 59-97. https://doi.org/10.1016/C2018-0-01479-6

3. del Brío, J.A; Junquera, B. A review of the literature on environmental innovation management in SMEs: implications for public policies. Technovation. 2003, 23, 939-948.

4. Hillary, R. Environmental management systems and the smaller enterprise. J. Cleaner Prod. 2004, 12, 561–569.

5. Nulkar, G. SMEs and environmental performance – A framework for green business strategies. Procedia Soc. Behav. Sci. 2014, 133, 130 – 140.

6. Budiyanto, S; Anies; Purnaweni, H; Sunoko, H.R. Environmental Analysis of The Impacts of Batik Wastewater Polution on The Quality of Dug Well Water in The Batik Industrial Center of Jenggot Pekalongan City. E3S Web Conf. 2018, 31,09008, https://doi.org/10.1051/e3sconf/20183109008

7. Kristijanto, A.I; Handayani, W; Levi, P.A.A. The Effectiveness of Anaerobic Baffled Reactor and Rotating Biological Contactor in Batik Wastewater Treatment. Makara J. Technol. 2011, 15, 168-172, https://doi.org/10.7454/mst.v15i2.935

8. Handayani, W; Kristijanto, A.I; Hunga, A.I.R. Are natural dyes eco-friendly? A case study on water usage and wastewater characteristics of batik production by natural dyes application. Sustain. Water Resour. Manag. 2018, 4, 1011-1021, https://doi.org/10.1007/s40899-018-0217-9

9. Lee K.E; Hanafiah M.M; Halim A.A; Mahmud M.H. Primary treatment of dye wastewater using aloe vera-aided aluminium and magnesium hybrid coagulants. Procedia Environ. Sci, 2015, 30, 56 – 61.

10. Pratiwi, N.I; Sari, F.R; Arifan, F; Wulandari, A.T; Alkian, I; Mustasjar, B; Aji, M.B.F.B. Batik Pemalang Organic Wastewater Composition and Simple Electrocoagulation-Filtration Treatment. IOP Conf. Ser. Earth Environ. Sci. 2020, 448, 012037, 1-9.

11. Daud, N.M; Abdullah, S.R.S; Hasan, H.A; Othman, A.R.; Ismail, N.I. Coagulation-flocculation treatment for batik effluent as a baseline study for the upcoming application of green coagulants/ flocculants towards sustainable batik industry. Heliyon. 2023, 9, e17284, 1-17. https://doi.org/10.1016/j.heliyon.2023.e17284

12. Soedjono, E.S.; Slamet, A.; Fitriani, N.; Sumarlan, N.M.; Supriyanto, A.; Isnadina, D.R.M.; Othman, N.B. Residual seawater from salt production (bittern) as a coagulant to remove lead (Pb2þ) and turbidity from batik industry wastewater. Heliyon. 2021, 7, e08268, 1-9. https://doi.org/10.1016/j.heliyon.2021.e08268

13. Rashidi, H.R; Sulaiman, N.M.N.; Hashim, N.A. Batik Industry Synthetic Wastewater Treatment Using Nanofiltration Membrane. Procedia Eng. 2012, 44, 2010-2012.

14. Febriasari, A.; Huriya; Ananto, A.H; Suhartini, M; Kartohardjono, S. Polysulfone–Polyvinyl Pyrrolidone Blend Polymer Composite Membranes for Batik Industrial Wastewater Treatment. Membranes. 2021, 11, 66, 1-17. https://doi.org/10.3390/membranes11010066

15. Sutisna; Wibowo, E.; Rokhmat, M.; Rahman, D.Y.; Murniati, R.; Khairurrijal; Abdullah, M. Batik Wastewater Treatment Using TiO2 Nanoparticles Coated on the Surface of Plastic Sheet. Procedia Eng. 2017, 170, 78 – 83.

16. Utami, M.; Wang, S.; Musawwa, M.M.; Mafruhah, L.; Fitri, M.; Wijaya, K.; Johnravindar, D.; Abd-Elkader, O.H.; Yadav, K.K.; Ravindran, B.; Chung, W.J; Chang, S.W.; Munusamy-Ramanujam, G. Photocatalytic degradation of naphthol blue from Batik wastewater using functionalized TiO2-based composites. Chemosphere. 2023, 337,139224, 1-11.

17. Annisa, N.; Nadisti, M.S.; Karamah, E.F.; Bismo, S. Degradation of batik dye wastewater in basic condition by ozonation technique in bubble column reactor. E3S Web Conf. 2018, 67, 04019, 1-5. https://doi.org/10.1051/e3sconf/20186704019

18. Lim, S.L.; Chu, W.L.; Phang, S.M. Use of Chlorella vulgaris for bioremediation of textile wastewater. Biores. Technol. 2010, 101, 7314–7322.

19. Almaamary, E.A.S.; Abdullah, S.R.S.; Ismail, N.I.; Idris, M.; Kurniawan, S.B.; Imron, M.F. Comparative performance of Scirpus grossus for phytotreating mixed dye wastewater in batch and continuous pilot subsurface constructed wetland systems. J. Environ. Manage. 2022; 307, 114534, 1-12.

20. Zakaria, N.; Rohani, R.; Mohtar, W.H.M.W.; Purwadi, R.; Sumampouw, G.A.; Indarto, A. Batik Effluent Treatment and Decolorization—A Review. Water. 2023, 15, 1339, 1-24. https://doi.org/10.3390/w15071339

21. Handayani, W.; Kristijanto, A.I.; Hunga, A.I.R. Behind the eco-friendliness of “batik warna alam”: Discovering the motives behind the production of batik in Jarum village, Klaten. Wacana. 2018, 19,1, 235-256. https://scholarhub.ui.ac.id/wacana/vol19/iss1/10/

22. Mukimin A, Vistanty H, Zen N, Purwanto A, Wicaksono KA. Performance of bioequalization-electrocatalytic integrated method for pollutants removal of hand-drawn batik wastewater. J. Water Process Eng. 2018, 21, 77–83.

23. Birgani, P.M.; Ranjbar, N.; Abdullah, R.C.; Wong, K.T.; Lee, G.; Ibrahim, S.; Park, C.; Yoon, Y.; Jang, M. An efficient and economical treatment for batik textile wastewater containing high levels of silicate and organic pollutants using a sequential process of acidification, magnesium oxide, and palm shell based activated carbon application. J. Environ. Manage. 2016, 184, 229-239.

24. Handayani W, Widianarko YB, Pratiwi AR. Addressing the Debate on the Eco-friendliness of Indonesian Batik by Water Footprint Approach. J. Environ. Sci. Sustain. Dev. 2023, 6, 1, 116-131. https://doi.org/10.7454/jessd.v6i1.1185

25. Ministry of Environment of Republic of Indonesia. [Regulation of The Ministry of Environmental Affairs 5/2014 on Quality Standard of Wastewater]. Jakarta. 2014.

26. Dinçer, A.R. Increasing BOD5/COD ratio of non‑biodegradable compound (reactive black 5) with ozone and catalase enzyme combination. SN Applied Sci. 2020, 2,736, 1-10. https://doi.org/10.1007/s42452-020-2557-y

27. Crini, G.; Lichtfouse, E. Wastewater Treatment: An overview, in: Crini G, Lichtfouse E (eds.), Green Adsorbents for Pollutant Removal. Environmental Chemistry for a Sustainable World, vol 18. Springer. Cham. 2018, 1-21. https://doi.org/10.1007/978-3-319-92111-2_1

28. Verma, S. Water and Wastewater Engineering Technology. CRC Press - Taylor & Francis. Boca Raton 2024.

29. Goel, R.K.; Flora, J.R.V.; Chen, J.P. Flow Equalization and Neutralization. In: Wang LK, Hung YT, Shammas, NK. (eds). Physicochemical Treatment Processes: Handbook of Environmental Engineering Vol 3. Humana Press. New Jersey. 2005, 21-45. https://doi.org/10.1385/1-59259-820-x:021

30. Daud, N.M.; Abdullah, S.R.S.; Hasan, H.A.; Ismail, N.I.; Dhokhikah, Y. Integrated physical-biological treatment system for batik industry wastewater: A review on process selection. Sci. Total Environ. 2022, 819, 152931, 1-17. http://dx.doi.org/10.1016/j.scitotenv.2022.152931

31. Yanto, D.H.Y.; Chempaka, R.M.; Nurhayat, O.D.; Argo, B.D.; Watanabe, T.; Wibisono, Y.; Hung, Y.T. Optimization of dye-contaminated wastewater treatment by fungal mycelial-light expanded clay aggregate composite. Environ. Res. 2023, 231,116207, 1-12. https://doi.org/10.1016/j.envres.2023.116207

32. Riduan, A.; Rainiyati; Heraningsih, S.F.; Badariah. Minimizing river pollution by batik dye wastewater using palm oil fuel ash (POFA) as an environmentally friendly, low-cost adsorbent alternative. J. Degraded Mining Lands Manage. 2022, 10,1, 3981-3989.

33. Al-Mahbashi, N.M.Y.; Kutty, S.R.M.; Bilad, M.R.; Huda, N.; Kobun, R.; Noor, A.; Jagaba, A.H.; Al-Nini, A.; Ghaleb, A.A.S.; Al-Dhawi, B.N.S. Bench-Scale Fixed-Bed Column Study for the Removal of Dye-Contaminated Effluent Using Sewage-Sludge-Based Biochar. Sustainability. 2022, 14,6484, 1-16. https://doi.org/10.3390/su14116484

34. Azha, S.F.; Ismail, S. Feasible and economical treatment of real hand-drawn batik/textile effluent using zwitterionic adsorbent coating: Removal performance and industrial application approach. J. Water Process Eng. 2021, 41, 102093, 1-12. https://doi.org/10.1016/j.jwpe.2021.102093

35. Nurddin, S.M.A.S.M.; Sufian, S.; Man, Z.; Rabat, N.E.; Ahmad, N. Effectiveness of Sequential Pre-treatment and Application of High-porosity Hybrid Fly Ash Geopolymer/alginate Adsorbent for the Treatment of Batik Wastewater. J. Chem. Health Risks. 2021, 11, 4, 345-356.

36. Handayani, P.A.; Cholifah U.; Ulviana, R.; Chafidz, A. “Batik” Industry Wastewater Treatment via Coagulation-Flocculation Process and Adsorption Using Teak Sawdust Based Activated Carbon. J. Bahan Alam Terbarukan 2019, 8, 1, 8-13. https://journal.unnes.ac.id/nju/index.php/jbat/article/view/20144

37. Mukimin, A.; Zen, N.; Purwanto, A.; Wicaksono K.A.; Vistanty, H.; Alfauzi, A.S. Application of a full-scale electrocatalytic reactor as real batik printing wastewater treatment by indirect oxidation process. J. Environ. Chem. Eng. 2017, 5, 5222–5232. http://dx.doi.org/10.1016/j.jece.2017.09.053

38. Pramugani A.; Shimizu, T.; Goto, S.; Argo, T.A.; Soda, S. Decolorization and Biodegradability Enhancement of Synthetic Batik Wastewater Containing Reactive Black 5 and Reactive Orange 16 by Ozonation. Water. 2022, 14, 3330, 1-11. https://doi.org/10.3390/w14203330

39. Kusworo, T.D.; Azizah, D.A.; Kumoro, A.C.; Kurniawan, T.A.; Othman, M.H.D. Fabrication, characterization, and application of PSf/Ni@ZnO amalgamated membrane for photocatalytic degradation of dyeing wastewater from batik industry. Mater. Today Chem. 2023, 30, 101493, 1-24. https://doi.org/10.1016/j.mtchem.2023.101493

40. Yuniati, M.D.; Rachmawati, V.; Nurjayati, R.; Marganingrum, D.; Lisdiana, A.; Noviardi, R.R.; Purwoko, W. COD Removal of Batik Wastewater using Microbial Immobilization System for Agricultural Purposes. IOP Conf. Ser. Earth Environ. Sci. 2022, 1059, 012032, 1-9. https://iopscience.iop.org/article/10.1088/1755-1315/1059/1/012032

41. Dewi RS, Sari AA, Fazrian RA. Decolorization of indigosol blue batik effluent using Lepiota sp. isolated from Baturraden Botanical Garden. IOP Conf. Ser. Earth Environ. Sci. 2022; 1017, 012027, 1-9. https://iopscience.iop.org/article/10.1088/1755-1315/1017/1/012027

42. Subramaniam D & Halim AA. Effect of electrochemical oxidation on biodegradability and toxicity of batik industry wastewater. AIP Conf. Proc. 2014, 1614, 597–602. https://doi.org/10.1063/1.489527015

43. Gani, P.; Sunar, N.M.; Matias-Peralta, H.; Latiff, A.A.A. Effect of pH and alum dosage on the efficiency of microalgae harvesting via flocculation technique. Int. J. Green Energy. 2017, 14, 4, 395-399. https://doi.org/10.1080/15435075.2016.1261707

44. Solayman, H.M.; Hossen, M.A.; Abd. Aziz, A.; Yahya, N.Y.; Leong, K.H.; Sim, L.C.; Monir, M.U.; Zoh, K.D. Performance evaluation of dye wastewater treatment technologies: A review. J. Environ. Chem. Eng. 2023, 11, 109610, 1-25. https://doi.org/10.1016/j.jece.2023.109610

45. Saleh, T.A. Interface Science and Technology Vol. 34: Surface Science of Adsorbents and Nanoadsorbents – Properties and Applications in Environmental Remediation, Academic Press – Elsevier. London. 2022.

46. Khulbe, K.C.; & Matsuura, T. Removal of heavy metals and pollutants by membrane adsorption techniques. Appl. Water Sci. 2018, 8, 19, 1-30. https://doi.org/10.1007/s13201-018-0661-6

47. Michalak, I.; Chojnacka, K.; Witek-Krowiak, A. State of the Art for the Biosorption Process—a Review, Appl. Biochem. Biotechnol. 2013, 170, 1389–1416. https://link.springer.com/article/10.1007/s12010-013-0269-0

48. Alias, S.S.; Harun, Z.; Azhar, F.H.; Ibrahim, S.A.; Johar, B. Comparison between commercial and synthesised nano flower-like rutile TiO2 immobilised on green super adsorbent towards dye wastewater treatment. J. Cleaner Prod. 2020, 251, 119448, 1-18. https://doi.org/10.1016/j.jclepro.2019.119448

[49] Handayani, T.; Emriadi; Deswati; Ramadhani, P.; Zein, R. Modelling studies of methylene blue dye removal using activated corn husk waste: Isotherm, kinetic and thermodynamic evaluation. South African J. Chem. Eng. 2024, 47, 15–27. https://doi.org/10.1016/j.sajce.2023.10.003

50. Ab.Aziz, N.A.H.; Md. Ali, U.F.; Ahmad, A.A.; Dzahir, M.I.H.M.; Khamidun, M.H., Abdullah, M.F. Non-functionalized oil palm waste-derived reduced graphene oxide for methylene blue removal: Isotherm, kinetics, thermodynamics, and mass transfer mechanism. Arabian J. Chem. 2023, 16, 104387, 1-11. https://doi.org/10.1016/j.arabjc.2022.104387

51. Tulashie, S.K.; Iddrisu, M.; Mensah, S.; Kotoka, F.; Adu, K. Adsorptive removal of reactive violet 5 azodye (V5R) with biochar: An ecofriendly technology. Sustain. Chem. Environ. 2023, 2, 100017, 1-9. https://doi.org/10.1016/j.scenv.2023.100017

52. Abd. Latif, N.A.F.; Nordin, A.H.; Ngadi, N.; Nabgan, W.; Jusoh, M.; Mohamad, Z.; Nawawi, M.G.M. Pineapple leaves based activated carbon for efficient removal of reactive black 5 in aqueous. Mater. Today Proc. 2021, 47,6, 1241-1245. https://doi.org/10.1016/j.matpr.2021.02.331

53. Iwuozor, K.O.; Ighalo, J.O.; Emenike, E.C.; Igwegbe, C.A.; Adeniyi, A.G. Do adsorbent pore size and specific surface area affect the kinetics of methyl orange aqueous phase adsorption? J. Chem. Lett. 2021, 2, 188-198. https://doi.org/10.22034/jchemlett.2022.327407.1048

Authors

Copyright (c) 2025 Widhi Handayani, Djoko Suwarno, Budi Widianarko

This work is licensed under a Creative Commons Attribution 4.0 International License.

Authors who publish with this journal agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgement of its initial publication in this journal.

- Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See The Effect of Open Access).